Product Description

![]()

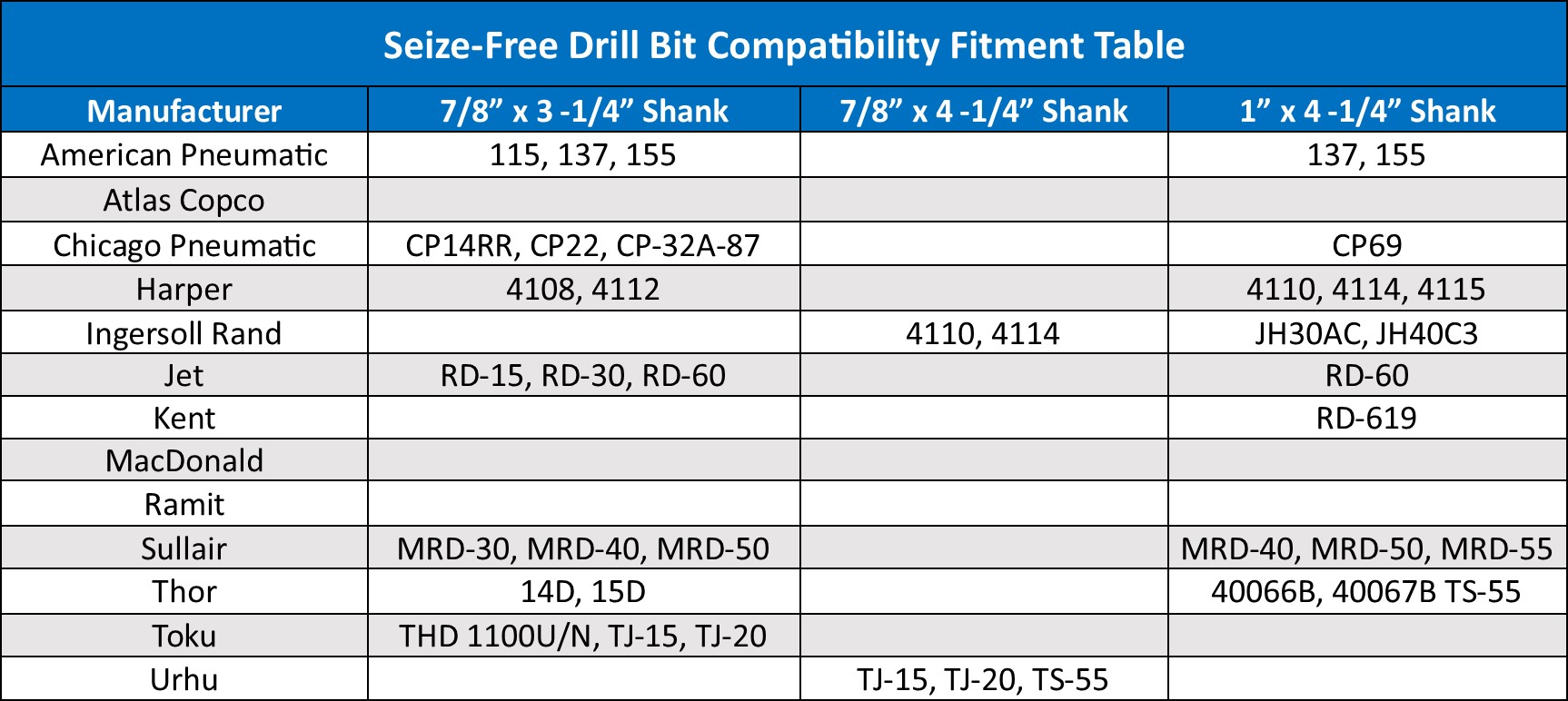

Sieze Free Drill Bits eliminate binding, a major cause of operator fatigue and injury when drilling through pavement. The spiral flutes create an "auger" type drilling action to resist binding from soft asphalt or frozen ground The bit is also effective in other types of pavement material including concrete and stone. The one piece design includes a carbide tip, that can be re-sharpened and blower holes at the tip for clearing debris from the cutting edges. Seize-Free Drill Bits are designed for use in Air Powered Rock Drills with 7/8" or 1" chucks. In use at major Gas Utilities throughout the United States and Canada.

Patented Seize-Free carbide drill bit combines a unique, spiral fluted design with increased air flow to the carbide tip. This prevents drill binding, the most common problem encountered when drilling through pavement overlays such as asphalt, concrete and stone.

Our drill bits perform with huge success in all utility construction applications. Carbide tipped drill bits used in rotary percussion hammers will drill hundreds of holes in granite, and a greater quantity in softer stone and concrete.

For best results and a longer tool life, the carbide insert should be sharpened frequently. It is not only easier to grind a small amount of carbide more often, rather than larger amounts of dull carbide less frequently, it also results in a minimal loss of carbide and maximum usable life of the drill bit. It is a good practice to sharpen the carbide insert after drilling 100-200 linear inches. This measure will vary accordingly to the hardness and abrasiveness of the material being drilled. It is important to maintain the original curvature of the carbide along with the 110 degree cutting angle during the sharpening process.

Dull carbide will cut slowly and will require more energy to drill a hole. This extra energy is absorbed by the drill, which can result in fractured carbides, failure of the steel, and/or a failure of the brazing which attaches the carbide into the steel. Dull carbides should be sharpened on a Green Silicone Carbide grinding wheel with a grit size of approximately 80 grit. These wheels are readily available at most industrial suppliers. Following these procedures will result in faster drilling, more holes drilled per bit, and fewer failures.

- DO grind carbide after 50 holes

- DO rotate use of drills

- DO grind to a 110 degree angle

- DO use cut outs as guides

- DO leave slight flat on the cutting edge

- DON’T hollow grind

- DON’T put J10 or L27’s in old adapters

- DON’T grind to a knife edge

- DON’T let drill get dull

- DON’T quench in water