Unique Products for the Underground Utility Professional

Shop by Brand

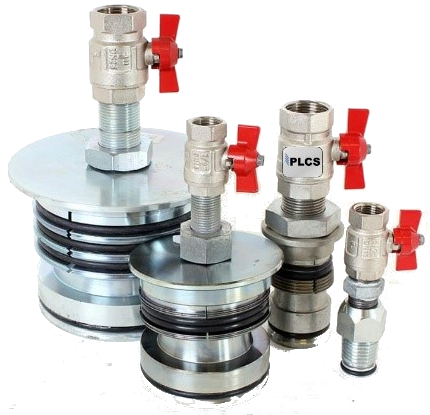

PE Test End Plug

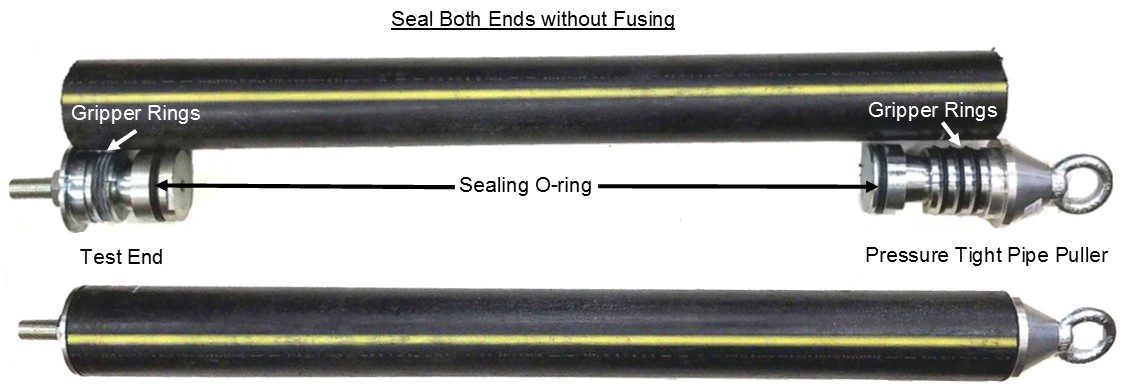

Decrease pipe pressure-test time, reducing downtime and saving project costs. A quick, simple and reliable method of testing PE (polyethylene pipe) without fusing end caps or installing mechanical fittings. Simply insert into the open ends of pipe, then tighten and begin testing. Testing can be performed on installed pipe or on the coil. Pressure test in minutes not hours. The Test End Plugs use the line test pressure to their advantage. The greater the test pressure the greater grip and seal. The gripper rings and sealing O-ring provide a safe, secure, leak-proof seal. Tested to the point of pipe failure without pressure release. Use overnight to keep open pipe ends clean and sealed. Can be used to maintain positive pressure on installed pipe sections. Saves an average of 2 man-hours per test. Compared to fusing end caps and mechanical fittings.

- 1/2" - 8" poly pipe

- An instant test connection to any PE pipe in any pipelining situation.

- The design is based on the very successful PLCS Pressure Tight Pipe Pullers in use on many directional drilling rigs for many years.

- Designed to work together with the Pressure Tight Pipe Pullers to seal both ends of a pipe without fusing for fast on-site testing.

- Inserts directly into open PE pipe end without special preparation.

- Tighten the nut and the grippers lock into position and will release immediately on demand.

- Test Ends provide a total barrier to ingress of soil or mud into the PE pipe, under even the worst site conditions.

- Heavy duty construction in plated steel for rugged durability.

- Minimal maintenance and replaceable components.

Tested to the point of pipe failure without pressure release. 2” SDR 11 gas pipe tested to bursting (Approx. 500 psi)